In today’s fast-paced and competitive business landscape, efficient and accurate labeling is crucial for product identification and brand recognition. Manual labeling processes are labor-intensive, time-consuming, and prone to errors. However, with the advent of bottle label machines, the labeling process has been revolutionized, ushering in a new era of productivity and precision. These versatile and automated wonders have found their way into various sectors, from the beverage industry to the pharmaceutical and food industries, streamlining workflows and ensuring consistent labeling across the board.

Understanding the Working Principles of Bottle Label Machines

Bottle label machines are mechanical devices designed to affix pre-printed labels onto specific parts of packaging containers. They are typically integrated into the final stages of the packaging operation, ensuring that products are properly labeled before they reach the market. These machines are equipped with various mechanisms and components that facilitate the smooth and accurate application of labels.

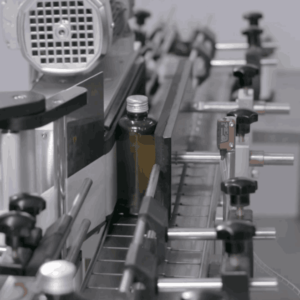

The Conveyor System

At the heart of a bottle label machine lies the conveyor system. This system ensures a continuous and controlled flow of products towards the labeling station. The items to be labeled are fed onto the conveyor at a constant speed, allowing the labeling machine to work seamlessly.

Mechanical Fixtures and Labeling Rollers

To maintain precision and consistency, bottle label machines incorporate mechanical fixtures and labeling rollers. These components separate the items at a fixed distance and push them in the direction of the conveyor. The labeling roller, in particular, is responsible for pressing the label against the article as it moves along the conveyor.

Label Application Movement

The label application movement is controlled by a drive roller and a reel. The drive roller intermittently drags the label strip, pulling it out of the spool while simultaneously pressing it against the article. An open-loop displacement control is employed on the reel to maintain the tension of the label strips, ensuring smooth and accurate application.

Sensor Control

To account for potential label slippage, a mark is often included on each label. This mark serves as a reference point to ensure that each label is correctly placed. A sensor reads this mark during the deceleration phase of the label, allowing the drive wheel to adjust the position and correct any errors.

Applications of Bottle Label Machines

Bottle label machines find extensive use in a wide range of industries, each with its unique requirements and challenges. Let’s explore some of the key sectors where these machines play a pivotal role.

1. Beverage Industry

The beverage industry demands high-speed labeling and precise positioning. Bottle label machines used in this industry often handle multiple labels per bottle, requiring advanced position control skills. As the appearance and materials of labels frequently change, flexibility and adaptability are critical for labeling machines in this sector.

2. Daily Chemical Industry

In the daily chemical industry, soft plastic containers and stringent beauty requirements pose challenges for labeling machines. Bubble exclusion control and precise label application are essential to ensure a flawless appearance. Bottle label machines in this sector must be capable of handling various container shapes and sizes.

3. Food Industry

The food industry utilizes multi-layer labels that provide manufacturers with ample space for product promotion. This poses unique challenges for labeling machines, as they must be capable of accurately applying labels on curved surfaces and ensuring proper adhesion. Flexibility and accuracy are key considerations in the design of bottle label machines in this sector.

4. Medical Industry

The medical industry relies on bottle label machines for the labeling of medical supplies. Self-adhesive labels are commonly used, serving not only as a means of identification but also providing additional functional uses. Labeling machines in this sector must meet stringent quality requirements and be capable of integrating seamlessly with the overall manufacturing process.

5. Pharmaceutical Industry

The pharmaceutical industry demands high-speed labeling machines to keep up with the fast-paced nature of pharmaceutical manufacturing. These machines must be capable of seamlessly integrating with upstream and downstream processes. Additionally, advanced features like front light inspection and automatic bottle holding after labeling are often required to ensure product quality and efficiency.

Conclusion

The advent of bottle label machines has transformed the labeling process in modern industry. With their automated and precise operation, these machines have revolutionized workflows and ensured consistent product identification across various sectors. From the beverage industry to the pharmaceutical and food industries, bottle label machines have become indispensable tools for enhancing productivity and streamlining operations.