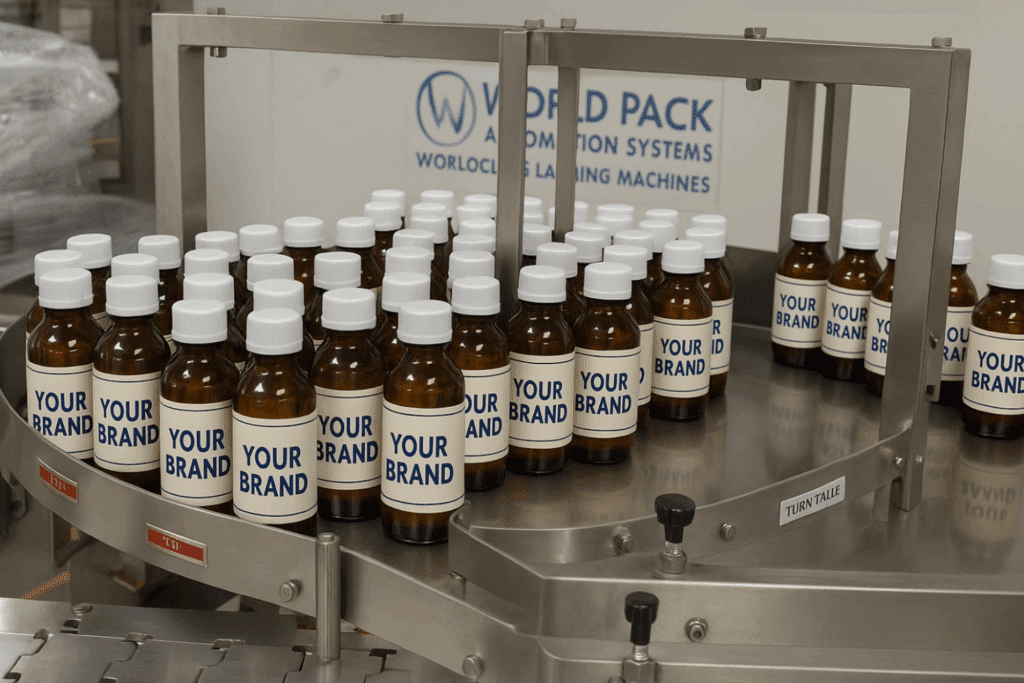

Supports Multiple Sizes : Easily adaptable for labelling multiple sizes of round bottle. (Min Ø 30)

Closed Frame Structure: Designed for compact access and cleaning, ensuring hygienic operation and low maintenance.

Durable Conveyor System: Features a SS Slat /Acetyl conveyor that ensures stable and consistent product movement.

Rotary In-feed Table: Positioned at the system’s entrance, equipped with side guides for smooth product alignment.

Rotary Out-feed Table: Located at the system’s exit; includes side guides and a built-in shelf for easy product collection.

Product Spacer: Uses a high-grip, sponge-coated belt to accurately space products; fully enclosed for maximum safety and adjustable speed for flexible cadence control.

Side Wrapping Unit: Comprises a high-grip rolling belt, complete with fine-tuning adjustments via tools and precision scales.

Optional – Easy Mobility: Built with four swivel wheels; the system can be moved effortlessly to suit different production layouts.

To learn more about how wrapround labelling machines can optimize your production process, contact Worldpack Automation Systems. Our experts will help you choose and implement a solution tailored to your specific needs.